Dongguan Zongtai Machinery Co., Ltd.

Main business: internal mixer, ten thousand horsepower, open mixer

-

Service Hotline

0769-22883796

product type:recommend

release time:2021-03-31

contact number: 0769-22883796

contact address: The Next Industrial Zone, Xincun Community, Wanjiang District, Dongguan City

- Product Introduction

- Product parameter

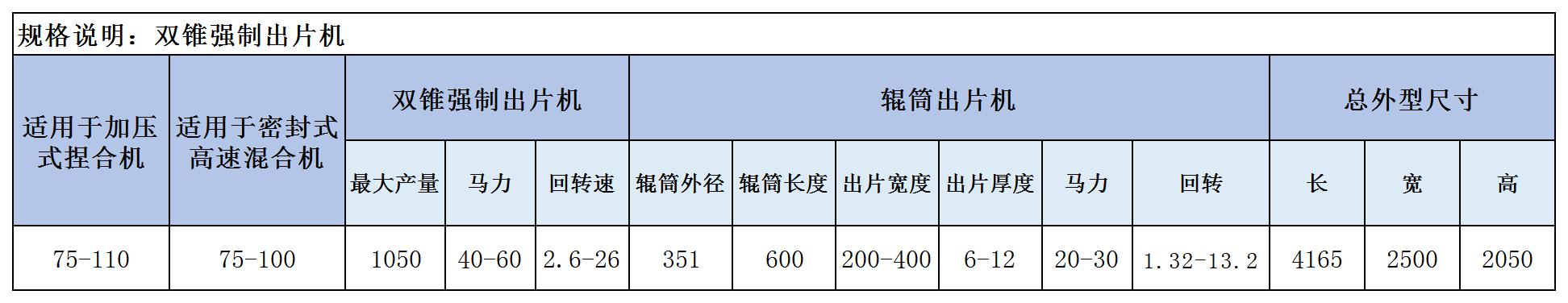

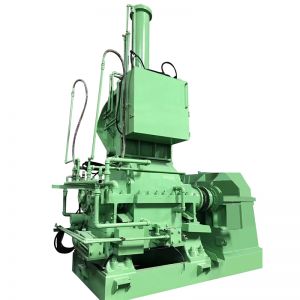

Purpose: Effectively solve the defects that are easy to occur in the subsequent rubber output due to the entrainment of impurities during the mixing process.

Product introduction:

1. The rubber compound has good mixing purity.

When the rubber material is effectively squeezed to the single-shaft screw by the two-cone extruder screw, it is sent to the die by rotating advancement, the impurities are filtered through the filter, and finally the rubber material is extruded from the die and cut into a high-pressure quantitative amount.

2. Save manpower, time and energy.

In traditional production lines, a shift of 22 and 18 mills requires 3 people to operate. In the case of multi-shift production, the multiples increase, but this machine only needs one person in a shift!

Both motors of this equipment use frequency conversion to start, equipped with a 75L 10,000-horsepower production line, the power consumption of the machine is about 20 degrees per hour, which can save more than 30 degrees per hour compared with traditional production lines! 3. Continuous automatic production, high yield.

During production, it reduces the time to replace the machine in the open refining line. The hot material of the internal mixer enters the machine, and the back section is directly connected. The pressure sensor of the output machine is uniquely designed by our company, and the color material is not changed. Bottom, can achieve 24 hours uninterrupted film, uniform thickness, good dispersion. It is conservatively estimated that the efficiency can be increased by more than 20%!

4. The unique conical screw design can twist all the rubber in without material accumulation and residual material.

5. Reduce safety hazards.

The traditional open refining production line requires employees to continuously replace the machine with rolls and packages. The material temperature is high and the heavy operation is cumbersome, and there is zero-distance contact with the machine for a long time, which is a high safety risk! This machine only requires employees to pull the material at the discharge port, which is safe and convenient.

6. Good cooling effect can ensure the stability of rubber material properties and quality.

7. Convenient material cleaning, simple maintenance, and long machine life.