Dongguan Zongtai Machinery Co., Ltd.

Main business: internal mixer, ten thousand horsepower, open mixer

-

Service Hotline

0769-22883796

product type:recommend

release time:2021-03-31

contact number: 0769-22883796

contact address: The Next Industrial Zone, Xincun Community, Wanjiang District, Dongguan City

- Product Introduction

- Product parameter

use:

This machine is mainly used for the forming and processing of rubber (tires, belts, fiber coating, etc.) and plastics (film, sheet, artificial leather, wallpaper, floor, etc.).

Product introduction:

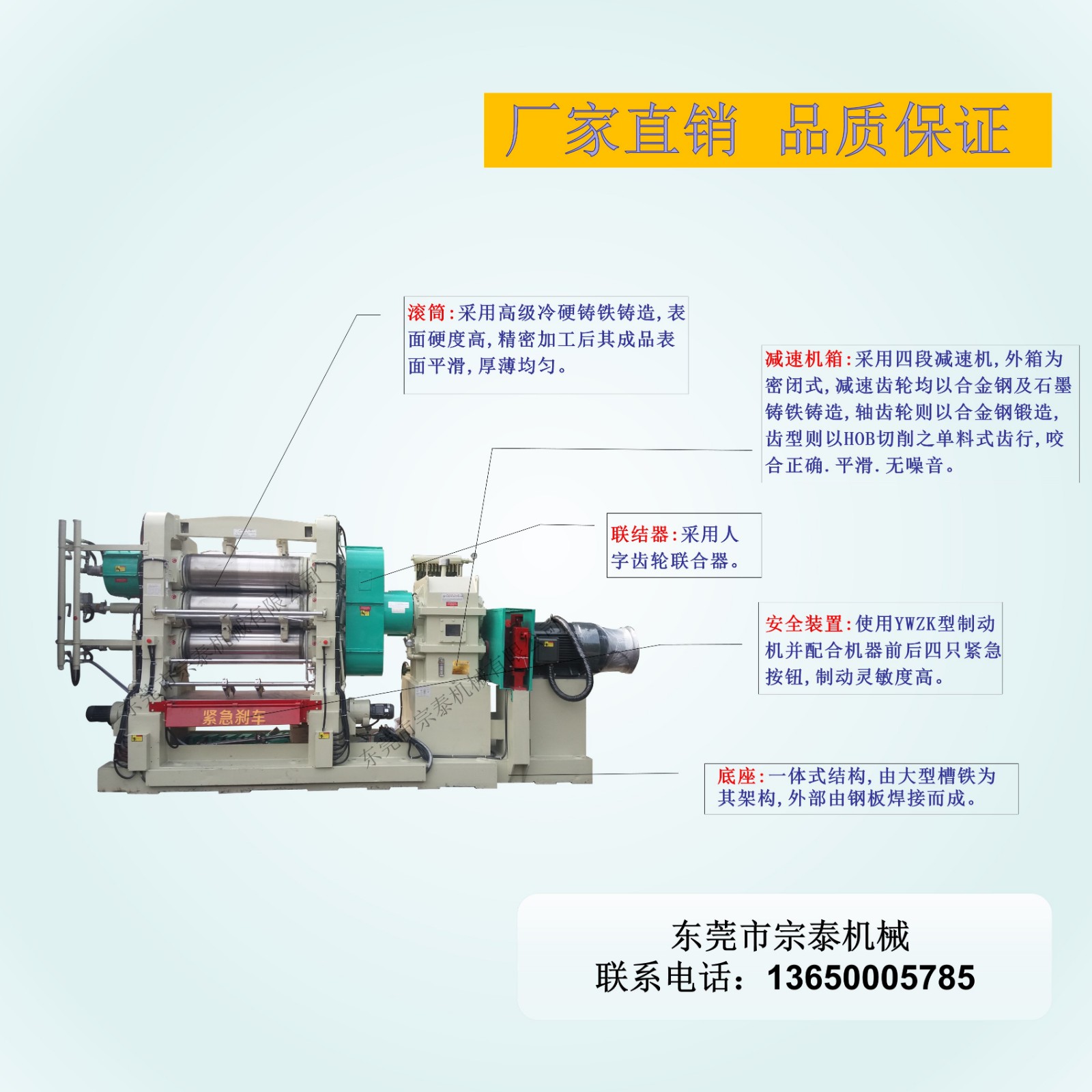

1. Roller: It is cast with high-grade chilled cast iron, and its hardened layer has high surface hardness. Its surface is precision processed and precision ground. Therefore, the surface of the finished product is smooth and uniform in thickness. The interior of the roller is hollow and the thickness is uniform. The cooling and heating efficiency is good, and the temperature difference of the roller surface is reduced.

2 Roller bushing: The roller bushing is composed of a bushing shell and a bearing, and the bushing shell is made of cast iron;

3. Rack: Upright F-shaped rack, cast in one piece, made of ductile iron or steel plate welded and formed by tempering to eliminate the impression force;

4 Coupling: adopts herringbone gear unit;

5. Reducer case: It adopts a four-stage reducer, the outer box is a closed type, the reduction gears are cast with alloy steel and graphite cast iron, the shaft gears are forged with alloy steel, and the tooth profile is a single-material tooth row cut by HOB. Correct. Smooth. No noise:

6. Base: One-piece structure, with large trough iron as its frame, and the outside is welded by steel plate;

7.Safe transposition: use YWZK type brake and cooperate with the four emergency buttons at the front and rear of the machine. An emergency foot brake is added directly below the front and rear operation. Its braking sensitivity can be pressed when the emergency button is pressed, and the drum stops within 1/4 circle. .

3. Working principle

Working principle: One of the necessary work parts of the calendering process: the friction angle p between the rubber material and the roller must be greater than the contact angle a, and the rubber material will be pulled into the roll distance to the four-roll calender during the calendering process. The roller works under a certain speed ratio to further knead the rubber material and increase its plasticity. Finally, through the minimum roller distance, it is calendered into a film with a certain thickness and width; under the action of the roller squeezing force, The film is squeezed on the textile or steel cord to form a certain pattern and shape, and multiple layers of films of different uses, colors and shapes can also be combined together.